3D Printing services

CMI supports all customers printing parts from Micro to Macro

dimensions.

Our printing technologies:

Laser

Bed fusion for Micro printing

Sizes: wall thickness size from 100 micron

Hight quality, high resolution, high mechanical properties

Materials:

Stainless steel , Inconel, Ti6Al4V, 1.4404(316L),304L,1.2709, IN718, 17-4PH, 15-5PH.

Laser bed fusion

Sizes: up to 420x420x42 0 mm

Materials: Titanium, Aluminum, Stainless steel , Inconel, Ti6Al4V, AlSi10Mg, Scalmalloy, 1.4404(316L),304L,1.2709, IN718, 17-4PH, 15-5PH.

Powder size: 20 micron up to 100 micron

EBAM – Electro Beam Additive Manufacturing

Sizes: up to 9 meters

Additively manufacture metal parts with significantly reduces machine time, material costs, and lead time compared to subtractive manufacturing.

Materials:

titanium, tungsten, tantalum, and nickel-based alloys in a matter of days, with very little material waste.

CMI can support you to design and produce parts based on 3D Metal/ polymer Printing Technology for :

1. Aerospace applications.

2. Medical devices

3. Industrial applications.

4. Automotive industry applications

5. Prototypes.

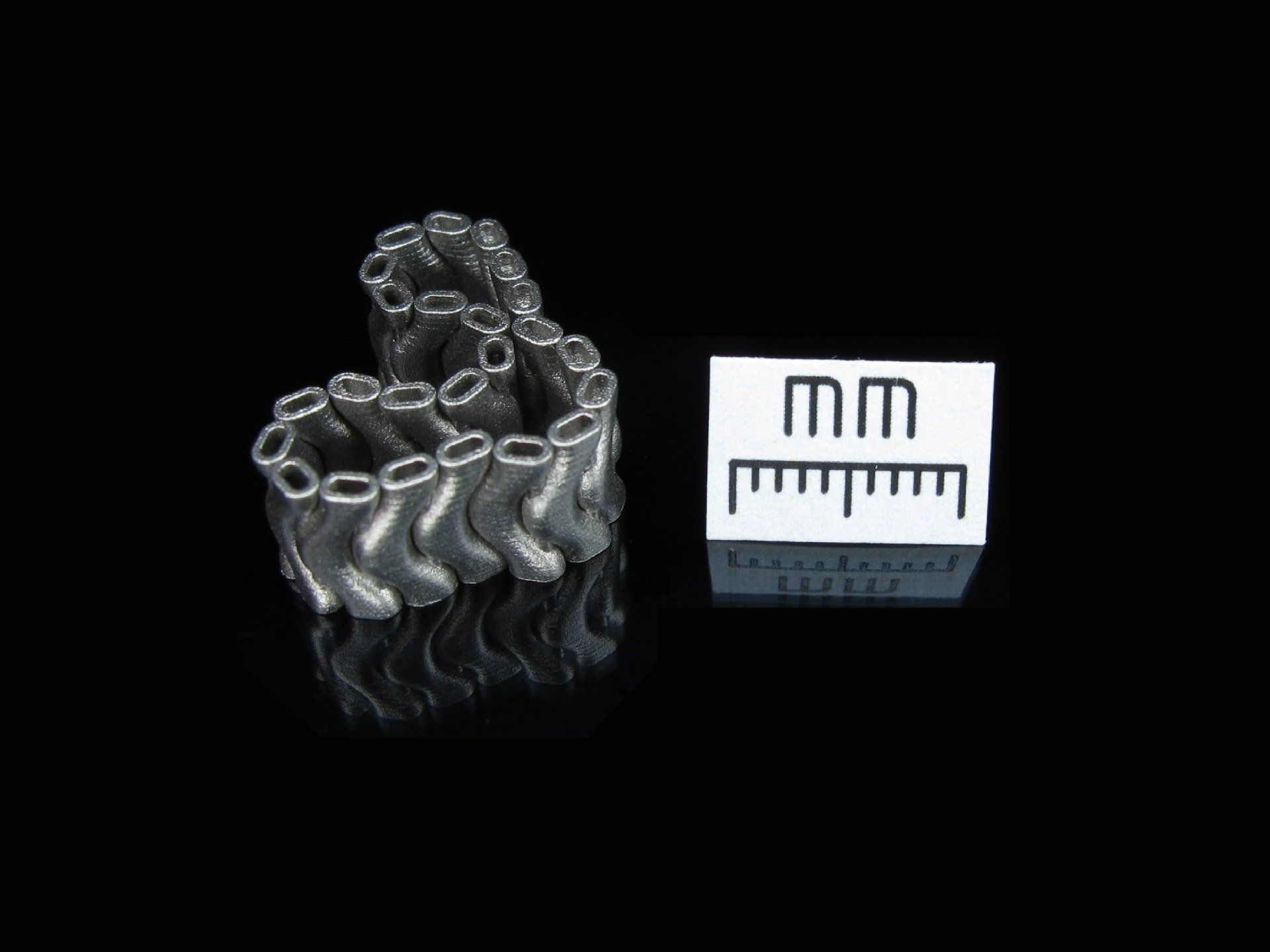

3D printing for medical devices

CMI 3D Printing specializes in 3D metal printing for medical device applications, 100 microns wall thickness.

Medical 3d printing offers exciting new ways of providing:

- Personalized cares.

- Better-performing medical devices.

- Cost effective versions of enhanced surgical tools.

- Flexible design & highly accurate models.

- Design specific tools in unique shapes

We offer:

3D printers

Printing services

R & D support from prototype to production.

Medical applications:

Dental, Orthodontic, Orthopedic, Cardiovascular, Audiology, Minimal invasive surgery, ophthalmology, and more…

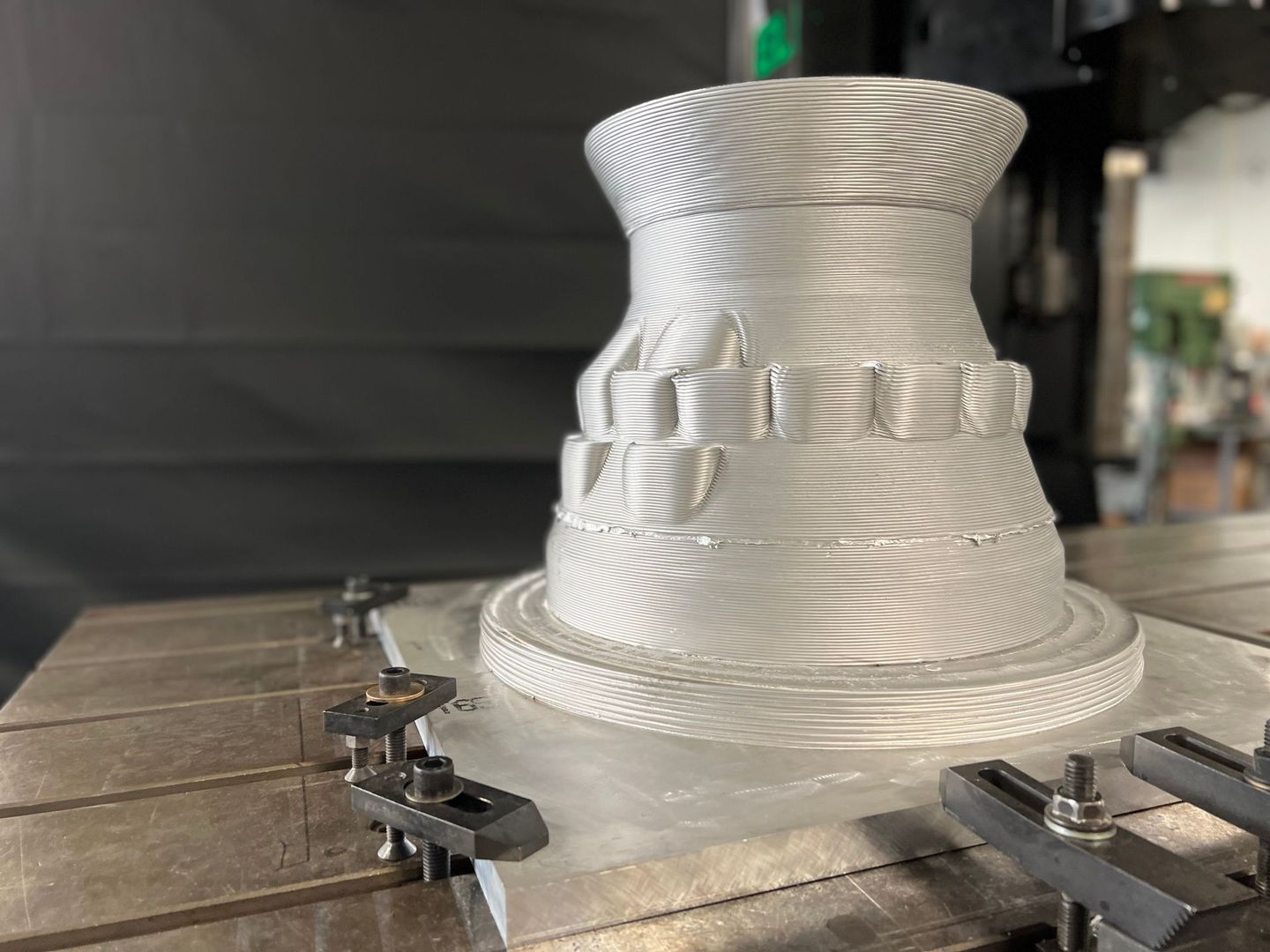

Polymer 3D printing center

CMI 3D Printing specializes in macro 3D polymer printing 1150x800x500

Materials: PLA, ASA, ABS, PA, HIPS, 3D850, PETG, ABS Medical, ABS HI, Nylon (PA12, PA12+CF, PA6+CF, PAG+GF), TPU (95A) and more.

Teaming with CMI will offer you:

- Personal care.

- Hight performing .

- Cost effective .

- Reliable solutions.

- Design support.

- Large form dimensions.

- R & D support from prototype & series production

- Parameter development.

3D Training & Projects Assistance

CMI 3D Printing provide our clients the opportunity to take

a step forward in moving towards the use of 3D

technology applications that are adjusted to your specific

company needs.

Training

Cmi 3D Printing provide our clients the opportunity to take a step forward in moving towards the use of 3D technology applications that are adjusted to your specific company needs.

Design

Optimization of 3D printing components and simulation of the manufacturing process.

Qualification

Implementation of equipment and consulting Quality management Additive Manufacturing.

Strategy

Scenario analysis, strategy consulting Additive Manufacturing and M&A projects.

Together with AMpower- Seminars for new design approach to aerospace products, medical and industrial production.

Universal Clamp - Matrix innovation

Matrix universal clamping system is a unique system.

This clamping system is adapting it self to any complicated shape and allows various job applications such as : machining, leveling, measurement , calibration and saving a huge amount of money, no need of new tooling, gigs.

Reusable as many times as you need.